Print at Lightning Speed With the Best DTF Printer

Our Peregrine x4 is the fastest DTF printer on the market and can deliver 100 full-color 11" x 11" DTF transfers in 30 minutes. For more information, see the Peregrine x4.

A 100-piece order will take about 30 seconds per shirt application. 100 pieces x 30 seconds = 50 minutes. Even if you run at the highest print quality (slowest print speed) and take your time with the pressing, you would produce over 50 shirts per hour! Compared to DTG at 20 prints per hour on their fastest settings (Not including the time to Pretreat). Oh, and don’t forget that DTF inks are generally 50% less than DTG. Our Ultra Bright DTF ink is formulated with more pigment to provide amazing vivid prints every time.

The process is a fully automated in-line production from screen to finished transfers. Just cut into singles and with a quick 10-15 second press you have a finished custom printed garment.

If this is too quick for your current needs, we also offer a cost-effective, two-head version of the Peregrine DTF transfer printer that will print 100 of the same 11” size transfer in 45 min

Print Systems for Smaller Shops and Home Businesses

If you have a small shop, work out of your home, or just want to create transfers for your own clothing line - Printomize offers a range of starter products that are very affordable for everyone. You can start creating DTF transfers with an investment as low as $13,995.00. Our Nebua as with all our systems) includes software, ink, film, adhesive powder, and phone/chat support .This package will have you ready to take orders in days not weeks.

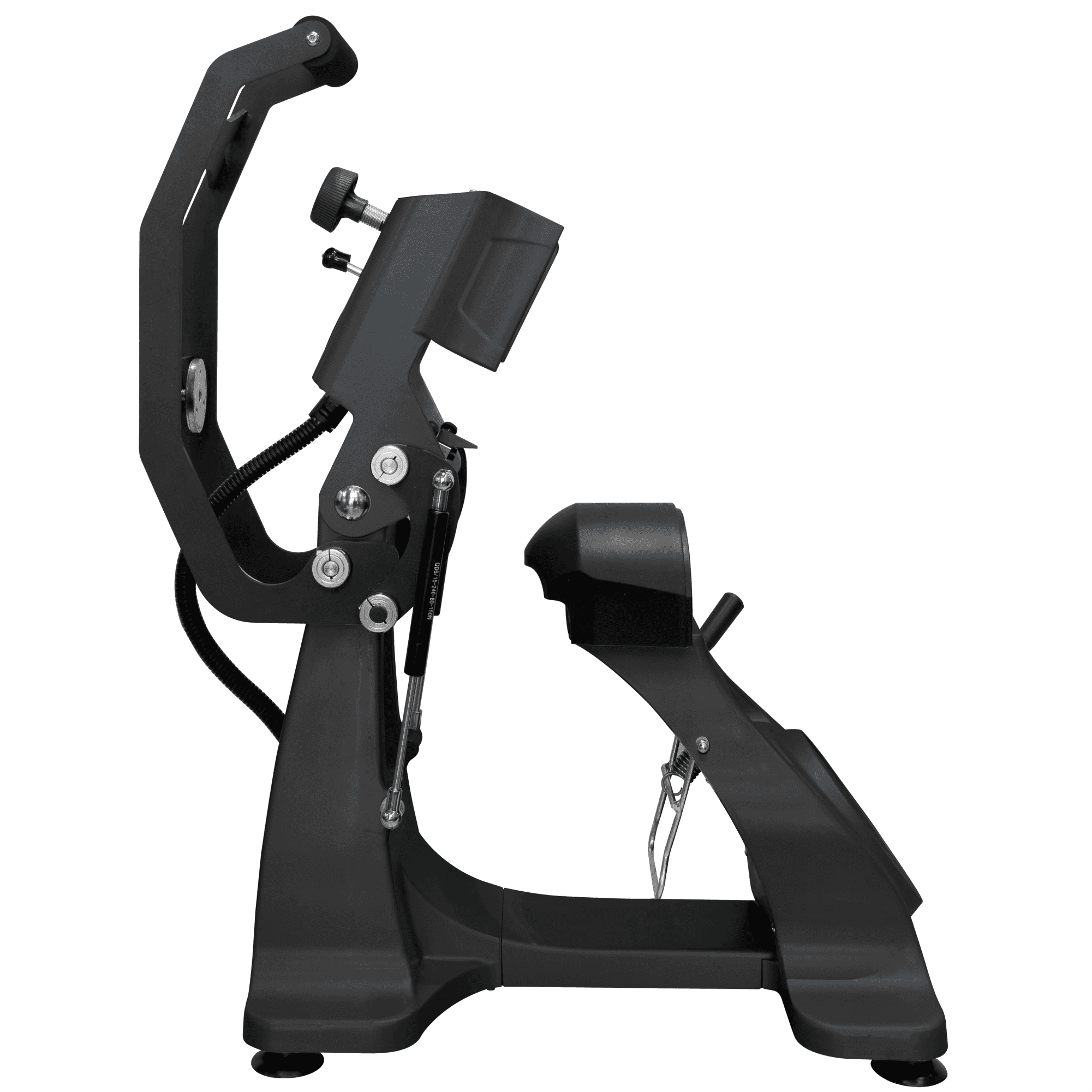

If you want to add a heat press for a direct heat transfer, we offer a wide range from our cost-effective MEM brand or the legendry USA-made Insta presses.

The Printomize America Difference

CEO Kristian Beasley has 30 years of experience in the garment decorating business with expertise in developing and manufacturing heat-applied transfers and patches for the sportswear industry. He was a pioneer in full digital heat-applied transfers and developed his first digitally printed transfer in 1998 using a Roland PC60 thermal tape printer (before the rise of Inkjet).

With extensive experience in the sports market, that demands lightweight, durable, soft, and stretchy prints – he has developed DTF transfers to the next level with Printomize. In addition, he is the owner of a large garment decorating business offering screen printing, embroidery, heat transfers and DTG. In other words, he understands the needs and challenges of this industry.

Printomize America Values Customer Service and Makes DTF Easy

We are available by phone, text, email, Skype – basically, whatever is your preferred way to communicate. We support you with artwork set up, special applications, large volume discounts, equipment issues and so much more! We are here to help you sell! Our mission has always been focused on promoting the success of our customers. We focus on long term relationships through practical knowledge, customer centric problem solving, and one stop shop convenience. We believe that the customer’s success will ultimately lead to our greater success.

Our vision is to be the one stop shop for all your DTF needs, with outstanding customer service to back up the printers, parts, and consumables. This includes real humans on the phone, instructional videos, and even marketing ideas for your company to help you sell more and increase your profits. There is no one that knows high volume DTF printing like Printomize America. Our team is at the leading edge of productivity enhancements. Our sales and support teams are capable, knowledgeable veterans of custom apparel printing.

“I have seen the future, and the future is DTF,” Beasley explains. “DTG will develop into a great solution for mass production as the technology evolves, and screen printing will always have its place. However, the ability to quicky produce quality full color heat applied custom transfers, that work on almost any fabric, with no pre-treatment - is game changing!”

Direct to Film Transfers (DTF) Offers Huge Benefits for Garment Printers

The revolution is here - DTF is the solution we have all been waiting for! If you are new and just starting in garment decorating, DTF is the answer! Direct to film is the best way to produce high-volume custom transfers for apparel. Especially custom t-shirts. If you are an experienced Screen Printer, DTF will make you more profitable! DTF makes the process of smaller run, 5+ color jobs more efficient and unrestricted.

Benefits from Direct to Film Transfers (DTF)

•Easy, intuitive and fast workflow from art to print

•Automated and scalable process that reduces labor costs.

•DTF will work on almost any fabric and has a much lower application heat - so no heat marks on sensitive fabrics.

•Finished product cost is 75% cheaper than DTG!!!

•Lowest startup cost compared to any other print system.

•Sharper and more vibrant prints compared to DTG.

•Largest industry print size - up to 24 inches wide x unlimited tall.

•We also offer our exceptional DTF transfers, delivered fast - so you can sell DTF with no commitment.

Challenges with DTG:

•Slow print speed of around 20 full front prints per hour.

•Steep learning curve and expensive equipment cost.

•DTG is mostly limited to 100% cotton and has inconsistent results printing on different fabrics and colors.

•Dark garments need to be pretreated and pressed before printing, which is time and labor consuming.

•Ink and pretreatment costs are expensive. DTF can save you up to 75% on costs!

•Limited to only printing on flat surfaces that fit on the machine.

•Inconsistent and inaccurate colors when printing on white or colors.

Challenges with screen printing:

•Extensive learning curve and requires a lot of expensive equipment.

•Convoluted process from art set up, film printing, screen burning, registration of colors, messy inks, and complex curing. More process, More problems!

•Requires a lot of space and labor costs to efficiently print.

•Set up takes hours for complicated job and custom colors need to be mixed by hand.

•Hard to find qualified and reliable labor for growth.

•Not cost effective for small runs with multiple colors.

•Fabric needs to be single layer and tacked to the pallet. Cannot print on double layered fabric or pockets!

DTG v DTF

Let’s make this easy! Here is the summary breakdown:

| Direct Comparisons | DTG: | DTF: |

| Consistent results on different fabrics | No | Yes |

| Works on many fabrics? | Only Cotton | Almost Any |

| Pretreat/drying is time consuming, therefore labor cost consuming | Pretreat | None |

| Must have equipment in house | Yes | Can buy |

| Ink costs are inexpensive | No | Yes |

| Total Equipment cost | $20k to $500k+ | $3k to $40k |

| Bright and consistent colors | No | Yes |

| Ability to print on hard to print areas and largest print size | No | Yes |

| Total labor and raw material costs | High | Low |

| Time to print 100 shirts with large front print from start to finish | 6 Hours | 2 Hours |